Thanks to our professional expertise and the diversity of medical devices we have developed, registered and produced over several decades, we are proud to bring together a pool of skills within a human-sized structure capable of extraordinary responsiveness.

Located between Vevey and Saint-Imier in Switzerland, we have assembled a multidisciplinary team able to support your projects from the initial idea through to completion.

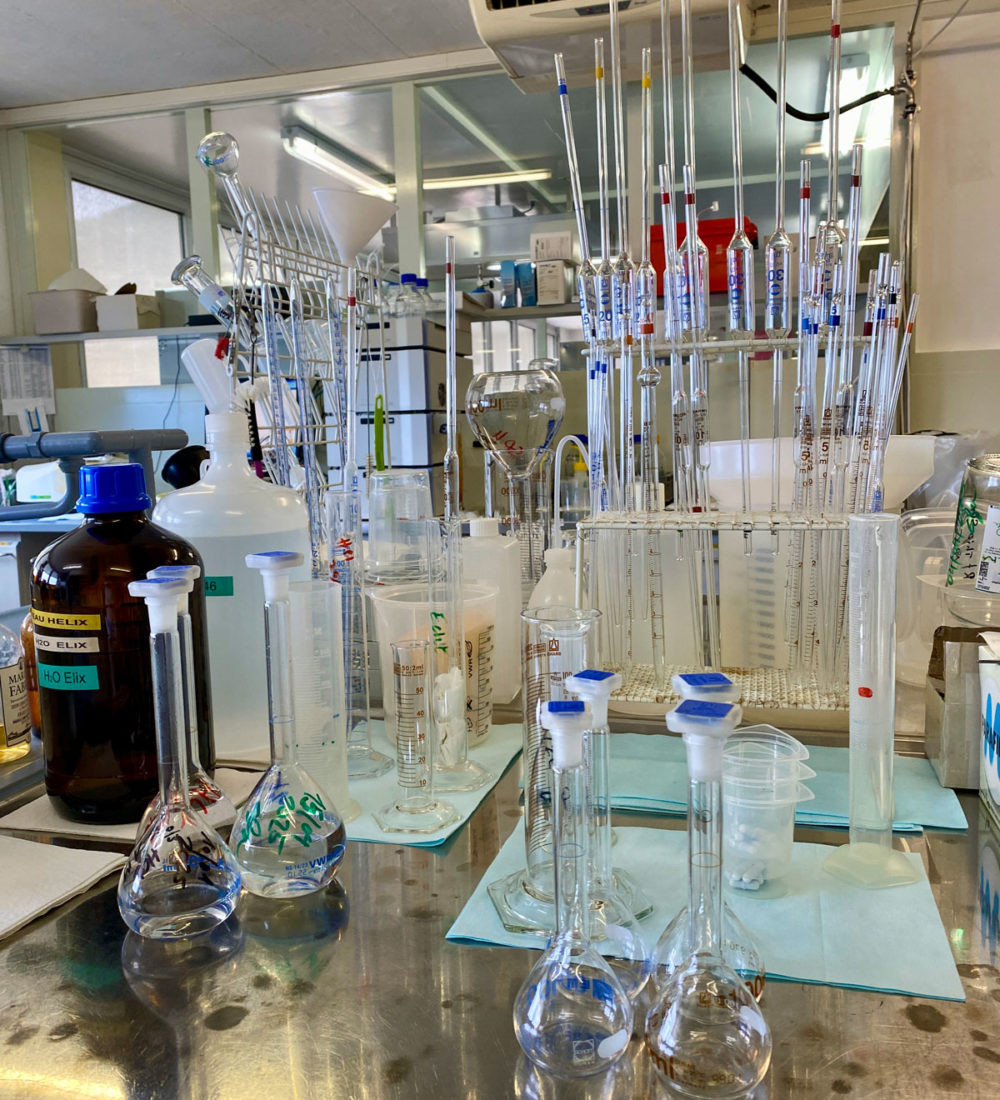

Our three main activities are laboratory production (gels, powders, liquids, pastes, cements), mechanical production (instruments and more) and thermoplastic injection process (containers, cannula, tips).

As a matter of fact, we are able to offer you the possibility to manufacture all your products within our two facilities — Produits Dentaires SA and Cemiplast SA — from formulation to packaging itself, including instruments and delivery devices designed to provide the user with an optimal experience when using your clinical solutions.